1. Introduction to Stone Crusher Plant Modules

A modular stone crusher plant is a flexible and customizable solution for processing various types of materials, such as aggregates, minerals, ores, and recycled materials. The term "modular" refers to the ability to configure the plant components into modules or sections that can be easily transported, assembled, and reconfigured to meet specific production requirements.

2. Benefits of Using Pre-designed Modules

2-1. Cost-effectiveness and Time-saving Benefits

The modular stone crushing and screening plants are competitively priced and have lower project costs because less engineering and planning is required. You also save over the lifecycle of the plant thanks to the reliability of our crushers and screens, and well-designed steel structures.

These modular equipment can become a complete solutions quickly, giving you optimized process performance and controlled budget and delivery time for the best return on your investment.

Standard Modular Plant offers a highly convenient solution for rapid production. Each part of the plant and the project layout are designed in advance. As to project delivery and test-run, it is quicker than traditional crushing plants.

2-2. Quality Control and Standardization

All standard modular plants are pre-designed and ready to run. Parts of the plant are bolted together, making them easy to disassemble. When there's a need to relocate the plant to another project site, it can be taken apart by using basic tools and quickly reassembled for production start-up.

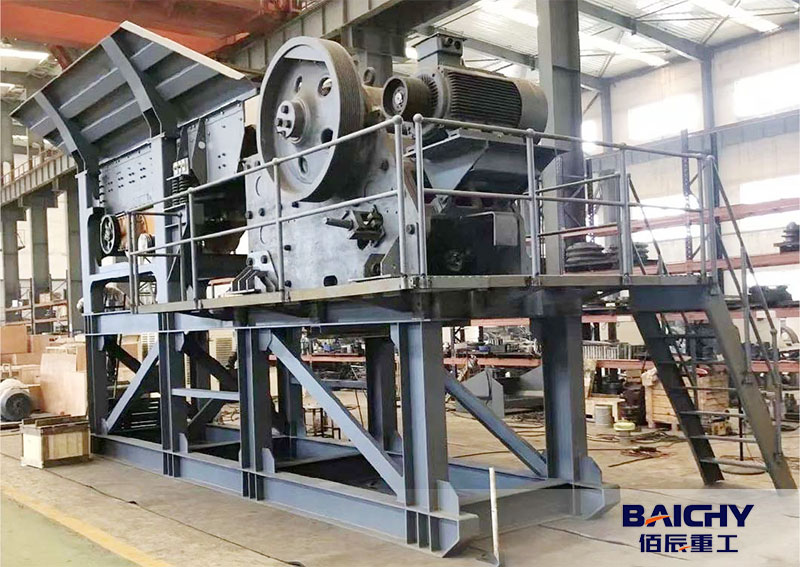

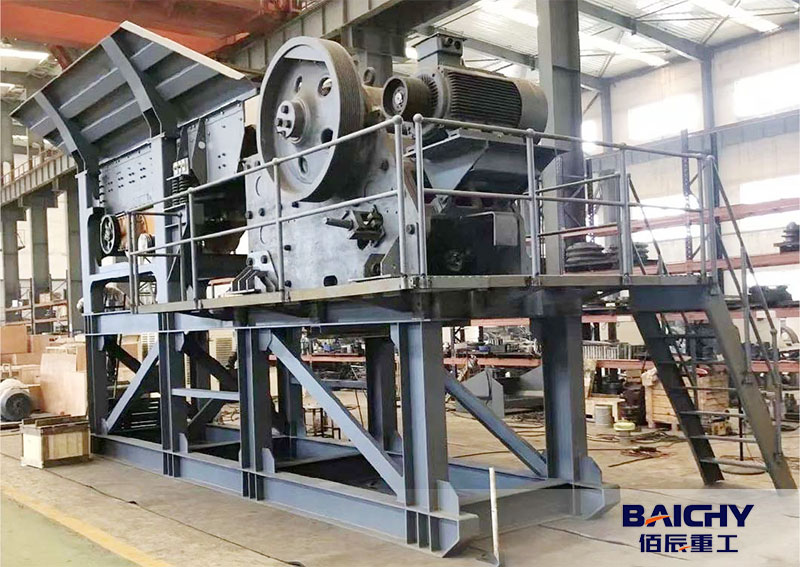

Modular Jaw Crusher has a fully painted steel structure including walkways, steps, guardrails and product conveyor.

This product is ideal for quarries and mines applications as well as C&D recycling, and integrates well with established systems or working independently.

3. Types of Pre-designed Modules Available

3-1. Primary Crushing Module

This module typically includes a primary jaw crusher or gyratory crusher, along with a feeder for initial material feeding. The primary crusher is responsible for reducing the size of the raw material to a manageable size for further processing.

3-2. Secondary Crushing Module

These modules consist of secondary and tertiary crushers, such as cone crushers or impact crushers, which further reduce the size of the material to the desired final product size. Multiple crushing stages may be incorporated to achieve the required particle size distribution.

3-3. Screening Module

The screening module includes vibrating screens or deck screens that separate the crushed material into different size fractions. This allows for the classification of the material into various products based on size, such as aggregates for concrete, asphalt, or railway ballast.

3-4. Conveying Module

Conveyors are used to transport the processed material between different stages of the crushing and screening process, as well as to stockpile the final products for storage or transportation. Modular conveyor systems can be easily integrated into the plant layout to optimize material flow.

4. Installation and Assembly Process

4-1. Strictly select the installation base before the formal installation. Generally, some sufficiently hard ground such as concrete will be selected to ensure that the mobile crushing station is installed firmly.

4-2. Check the environment around the base after selecting the installation base, mainly to see if there are any obstacles.

4-3. Fix the mobile crushing station with anchor bolts after it is installed on the concrete base. During the process, pay attention to the verticality of the main machine and the horizontal. In addition, check whether the bolts of various parts are loose and the tightening effect of the main machine door;

4-4. Configure the power cord and control switch according to the power size of the selected mobile crushing station equipment. After these preparations are completed, carry out a no-load test run. If the car keeps normal operation, the mobile crushing station can be put into production.

Modular stone crushers represent a paradigm shift in the crushing and screening industry, offering a potent combination of efficiency, flexibility, and scalability. It is widely applied in mining, construction, or aggregate production. As a professional large-scale mining crushing equipment manufacturer, Baichy produces high-quality mobile crushing plant and other mining equipment, also has professional technicians to assist in the installation. In addition, we can also provide users with free equipment operation technician training and other services. If you have any needs, please feel free to visit us.

People Also Frequently Asked For - FAQ

How does a stone crushing plant work?

Stone crusher plants typically consist of a primary crushing unit and a secondary crushing unit. The primary crushing unit is responsible for breaking down the larger, incoming material, while the secondary crushing unit is used to process the material further and produce a finer grade.

What is the purpose of a crushing plant?

A Crushing plant is one-stop crushing installation, which can be used for rock crushing, garbage crushing, building materials crushing and other similar operations. Crushing plants may be either fixed or mobile.

Is Stone Crusher a profitable business?

The stone crushing business has the potential to be profitable, given the continuous demand for crushed stones in construction projects.

2025-04-02

2025-04-02

86-15093113821

86-15093113821

86-15093113821

86-15093113821